Drilling Machines

SERIES 3- AXIS CNC SPARK-EDM

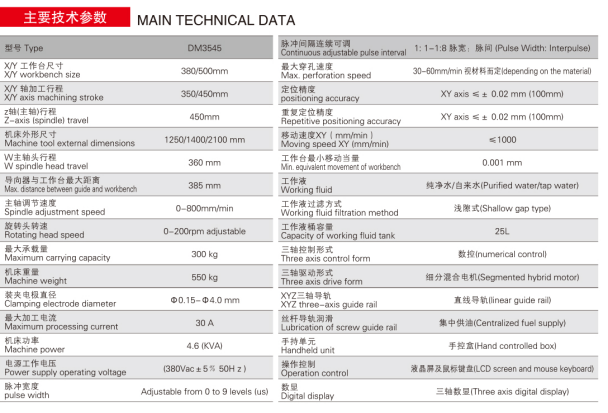

DM3545

Scope of Application:

This machine uses a brass or copper electrode tube and high-frequency pulse power to efficiently drill deep holes in conductive materials such as stainless steel, hardened steel, copper, aluminum, and cemented carbide. It achieves hole diameters of 0.15mm–3.0mm with a depth-to-diameter ratio exceeding 300:1, even on inclined or curved surfaces.

Ideal for machining tasks such as mold holes, thread holes, chemical fiber spinneret holes, filter plates, cooling holes in engine blades and cylinder bodies, hydraulic and steam valve paths, and more. Additionally, it can remove broken drill bits and taps without damaging the original workpiece.

SERIES ECONOMICAL HIGH-SPEED CNC SPARK-EDM

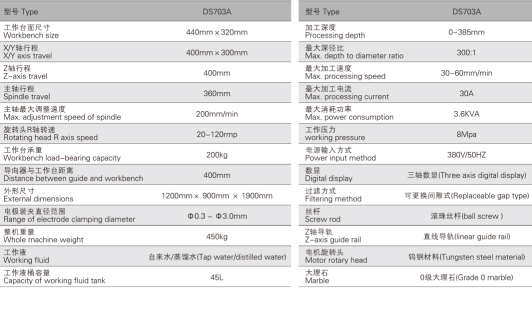

DS703A

Scope of Application:

This high-speed CNC Spark-EDM machine is designed for deep hole processing in conductive materials such as stainless steel, hardened steel, cemented carbide, copper, and aluminum. It is ideal for tasks like threading holes for electric spark cutting, chemical fiber spinnerets, group holes on filter and sieve plates, heat dissipation holes in engine blades and cylinder blocks, and oil or air passage holes in hydraulic and pneumatic valve bodies.

The machine features a worktable with digital display devices for the X and Y axes and uses purified or tap water as the working fluid. It can drill through inclined and curved surfaces with ease, achieving a depth-to-diameter ratio of over 200:1. Additionally, it can remove broken drill bits and taps without damaging the original hole or thread, ensuring high precision and efficiency in operations.

Product Technical Catalog